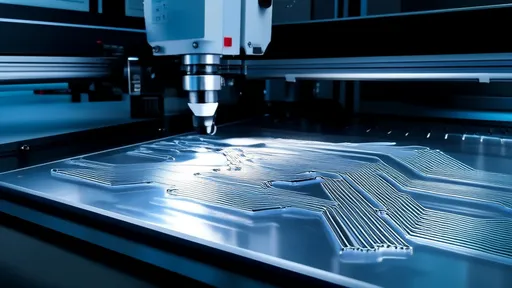

The world of electronics manufacturing is undergoing a quiet revolution as researchers develop innovative methods to create flexible, rewritable circuits using liquid metal inks. This groundbreaking technology promises to transform how we design and produce electronic devices, offering unprecedented flexibility and sustainability in circuit fabrication.

At the heart of this innovation lies a special class of conductive inks composed of low-melting-point alloys that remain liquid at room temperature. Unlike conventional circuit printing methods that rely on rigid materials and permanent etching processes, liquid metal inks enable the creation of circuits that can be erased and redrawn multiple times without damaging the substrate.

The Science Behind Liquid Metal Inks

These remarkable inks typically consist of gallium-based alloys, often combined with indium and tin to achieve optimal conductivity and viscosity. Gallium's low melting point (29.8°C) means it stays liquid in most environmental conditions while maintaining excellent electrical properties. When applied to flexible substrates like polymer films or paper, the liquid metal forms conductive traces that can withstand bending and stretching without losing functionality.

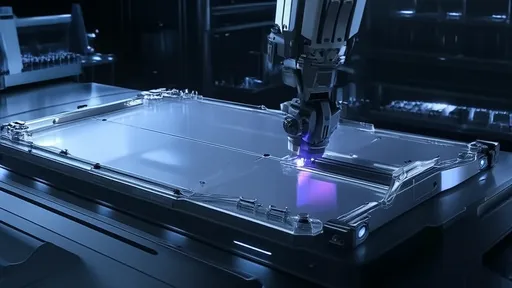

Researchers have developed various application techniques for these inks, including direct-write printing, screen printing, and even simple syringe-based deposition. The liquid metal naturally forms a thin oxide skin upon exposure to air, which helps maintain structural integrity while still allowing electrical conductivity. This unique property enables the creation of stable circuit patterns that don't require additional curing or sintering processes.

Rewritable Circuit Technology

What sets liquid metal circuits apart is their reusability. Traditional printed circuits are permanent once fabricated, but liquid metal traces can be selectively removed or reshaped using mechanical, chemical, or electrical methods. Some systems employ a specialized "eraser" that breaks the oxide skin and allows the metal to be wiped away, while others use electrochemical processes to dissolve and redeposit the metal as needed.

This rewritable capability opens up fascinating possibilities for prototyping and education. Engineers can test multiple circuit designs on the same substrate, making real-time adjustments without generating electronic waste. In educational settings, students can experiment with circuit layouts repeatedly, gaining hands-on experience with electronics design at minimal cost.

Applications in Flexible Electronics

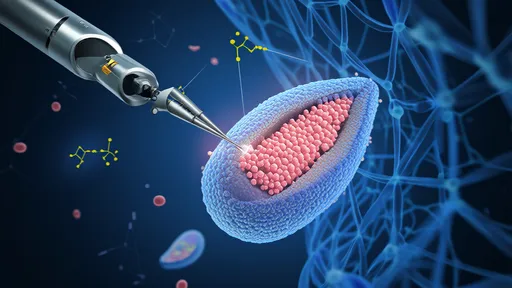

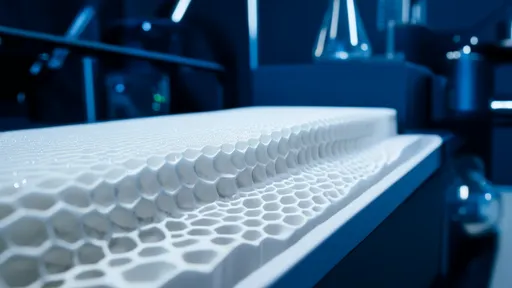

The flexibility of these circuits makes them ideal for emerging technologies that require conformable electronics. Wearable devices can incorporate liquid metal circuits that stretch and move with the body, maintaining reliable electrical connections during physical activity. Medical sensors benefit from this technology by conforming to the contours of skin or organs without causing discomfort or signal degradation.

In robotics, liquid metal circuits enable the creation of soft, flexible robots with integrated sensing and control systems. These circuits can be embedded within elastomeric materials, allowing for complex movements and adaptive shapes that rigid circuits would prohibit. The self-healing properties of some liquid metal formulations further enhance durability in these demanding applications.

Environmental Advantages

Traditional circuit manufacturing generates significant waste through chemical etching and the disposable nature of many electronic components. Liquid metal printing offers a more sustainable alternative by reducing material consumption and enabling component reuse. The ability to erase and redesign circuits on the same substrate dramatically decreases electronic waste, while the non-toxic nature of gallium-based alloys presents fewer environmental hazards than conventional circuit materials.

Moreover, the low energy requirements of liquid metal circuit fabrication contrast sharply with the high-temperature processes needed for traditional printed circuit boards. This energy efficiency, combined with the potential for room-temperature manufacturing, could significantly reduce the carbon footprint of electronics production.

Challenges and Future Directions

Despite its promise, liquid metal circuit technology faces several hurdles before achieving widespread adoption. The relatively high cost of gallium compared to copper presents an economic challenge, though recycling programs could mitigate this issue. Researchers are also working to improve the resolution of printed features to compete with conventional lithographic techniques.

Another active area of research focuses on developing hybrid systems that combine liquid metal traces with conventional electronic components. Creating reliable interconnects between these dissimilar materials while maintaining flexibility remains a technical challenge that teams worldwide are addressing through innovative interface designs.

Looking ahead, scientists envision a future where liquid metal circuits enable truly transient electronics - devices that can be completely erased and recycled when no longer needed. This could revolutionize product lifecycles and help address the growing problem of electronic waste. Other promising directions include bio-integrated electronics and foldable devices that take full advantage of the technology's unique properties.

As research progresses, liquid metal ink technology continues to demonstrate its potential to reshape electronics manufacturing. From flexible wearables to sustainable circuit production, this innovative approach offers solutions to many of the limitations facing conventional electronics. While challenges remain, the future appears bright for rewritable, flexible circuits that combine performance with environmental responsibility.

The coming years will likely see this technology transition from laboratory prototypes to commercial applications, potentially changing how we think about and interact with electronic devices. As the field matures, liquid metal circuits may well become a cornerstone of next-generation electronics, enabling designs and applications we can only begin to imagine.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025