The automotive industry stands on the brink of a revolution, one that promises to transform the humble tire into a self-healing marvel of modern engineering. Self-repairing elastomers, a class of smart materials capable of autonomously recovering from damage, are poised to redefine the safety, durability, and sustainability of tires. This breakthrough could render punctures and wear a relic of the past, ushering in an era where tires maintain their integrity with minimal human intervention.

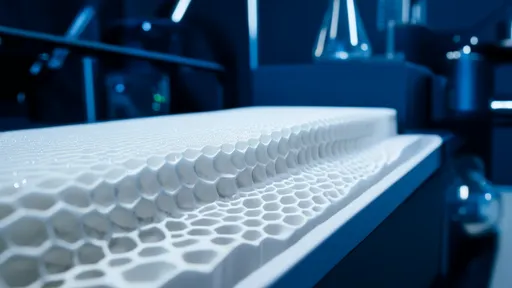

At the heart of this innovation lies the science of elastomers—polymers with elastic properties, which form the basis of conventional tires. Researchers have long sought to enhance these materials by embedding them with self-healing capabilities. The latest advancements leverage dynamic covalent chemistry, where molecular bonds can break and reform under specific conditions. When a tire sustains damage, these bonds reactivate, effectively sealing cracks or punctures without external triggers. Imagine a tire that "heals" itself while you drive, eliminating the need for immediate repairs or replacements.

The implications for safety are profound. Blowouts and sudden pressure loss, often caused by unnoticed punctures, account for a significant percentage of road accidents. Self-healing tires could mitigate these risks by maintaining structural integrity even after sustaining damage. For electric vehicles (EVs), where tire wear is accelerated due to instant torque and heavier batteries, this technology offers a dual benefit: extended tire life and reduced maintenance costs. Fleet operators, in particular, stand to gain from fewer downtime incidents and lower operational expenses.

Beyond performance, sustainability drives the adoption of self-repairing elastomers. Traditional tires contribute substantially to global microplastic pollution as they wear down. By prolonging tire lifespan, self-healing materials could dramatically reduce this environmental burden. Moreover, the reduction in tire replacements aligns with circular economy principles, minimizing resource extraction and waste. Manufacturers are already exploring bio-based elastomers to further enhance the eco-credentials of these next-generation tires.

Despite the promise, challenges remain. Scaling production while maintaining cost-effectiveness is a hurdle, as self-healing elastomers currently involve complex synthesis processes. Durability under extreme conditions—such as prolonged exposure to UV radiation or sub-zero temperatures—also requires further testing. However, industry leaders like Michelin and Goodyear have unveiled prototypes, signaling confidence in overcoming these obstacles. Collaborations with academic institutions are accelerating progress, with recent studies showcasing elastomers that heal repeatedly without losing elasticity.

Consumer adoption will hinge on education and trust. Drivers accustomed to traditional tires may need reassurance about the reliability of self-healing technology. Transparent communication about performance metrics—such as healing speed and maximum repairable damage—will be crucial. Early adopters, likely in commercial transportation, could pave the way for broader acceptance as real-world data validates the technology’s efficacy.

The road ahead is clear: self-healing elastomers represent more than an incremental upgrade. They embody a paradigm shift in how we conceive tire longevity and vehicle safety. As research advances and manufacturing scales, the vision of tires that outlast the vehicles they support inches closer to reality. For an industry under pressure to innovate sustainably, this technology isn’t just smart—it’s indispensable.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025